Suzuki

Suzuki DF175AP White

|

These high-performance, mid-size Suzuki outboard motors are the perfect balance of power, fuel efficiency, and reliability. |

A REVOLUTION IN INNOVATIONWhether you’re boating for leisure or to make a living, our big-block range delivers the power and performance you demand. Suzuki’s DF175 is based on an inline four-cylinder DOHC powerhead with a 2,867cm³ (174.9 cu.in.) displacement. While the large displacement contributes greatly to producing exceptional acceleration and torque, it doesn’t mean that they are comparatively larger and heavier in size. On the contrary, Suzuki’s engineers have targeted this big block motor to be one of the lightest four strokes in the 175 HP class. |

|

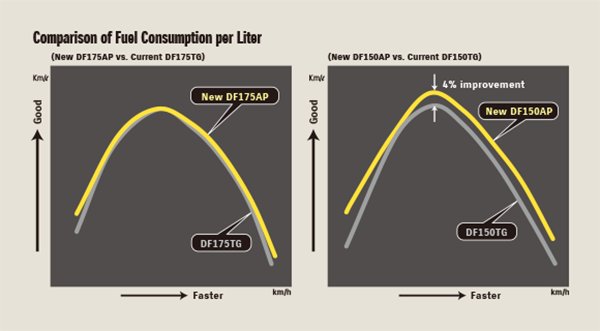

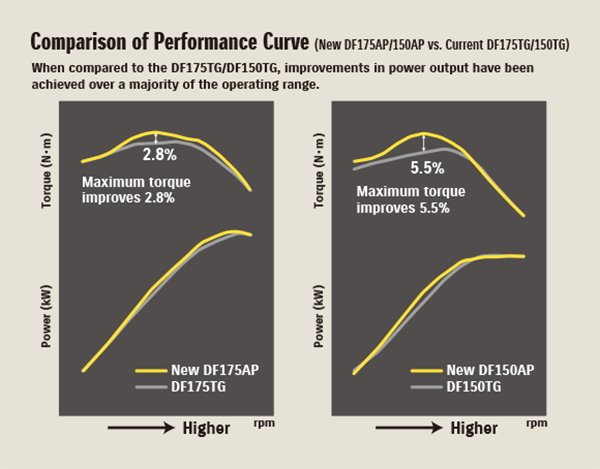

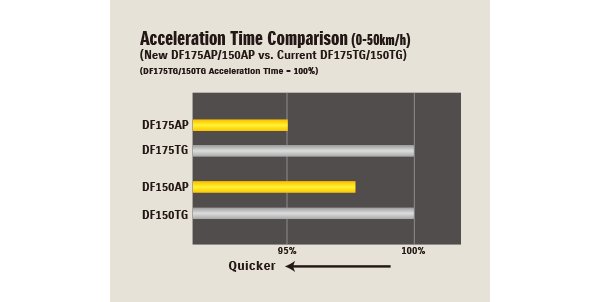

BIG BLOCK HIGH PERFORMANCE ENGINEThe new DF175AP/150AP development team based both of these new Suzuki outboards on a big block inline four-cylinder four-stroke engine with a 2,867cm3 displacement. The block is topped with a DOHC powerhead that provides four-valves per cylinder for high performance. While the large displacement allows both to deliver exceptional acceleration and velocity, our engineers made sure that the outboard’s final dimensions are as compact and lightweight as possible. Both outboards feature some of the best of Suzuki’s advanced technologies that have been developed to extend engine performance. |

HIGH 10.2:1 COMPRESSION RATIOCompression and displacement each play important roles in delivering performance and power output. Displacement has a direct effect on acceleration and torque so a bigger displacement is generally going to deliver more of both. Higher compression ratios allow the engine to get more output out of the combustion process resulting in noticeable improvements in performance and power. Drawing on our extensive motorsports experience and expertise in building race engines, Suzuki engineers have combined a 2,867cm3 displacement (the largest in each outboard’s class) with a high compression ratio of 10.2:1 to obtain great performance from these compact engines. |

|

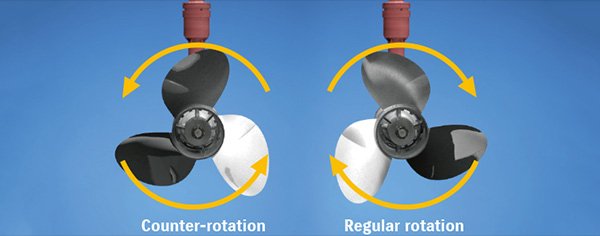

COUNTER BALANCER SYSTEMne of the inherent characteristics common to in-line four-cylinder engines when operating at high rpm is a secondary vibration that is directionally in line with the piston’s movements. To neutralize this vibration, Suzuki engineers utilize a secondary balancer system that counters the piston’s movement with a horizontal motion. To achieve this, the balancer is divided into left and right sections each rotating in an opposite direction at twice the speed of the crankshaft, effectively countering the secondary vibrations and producing smoother engine operation. |

O2 SENSOR FEEDBACK CONTROL SYSTEMA key sensor in the electronic fuel injection system, the O2 Sensor Feedback Control system provides accurate, real-time information that the ECU uses to manage the fuel/air ratio as operating conditions change. Utilized on many of Suzuki’s high-end outboards, the O2 Sensor Feedback Control system helps maintain optimum engine operating efficiency across the engine’s full operating range. |

|

SUZUKI PRECISION CONTROL ( ELECTRONIC THROTTLE AND SHIFT SYSTEM)Suzuki Precision Control is a technologically advanced computer-based control system that replaces the mechanical control cables found in conventional control systems with electronic wiring that eliminates the source of friction and resistance. While you enjoy smooth throttle and shift operation with minimal friction, the system’s computer is processing and transmitting commands in real-time to actuators at the engine that deliver precise throttle control with smoother, decisive shifting. This is most evident in the low rpm range where operation is noticeably smooth and accurate. When combined with Suzuki’s Lean Burn Control System it allows control of fuel and airflow to boost the limit of the controllable revolution range improving fuel economy over a wide operating range. Suzuki Precision Control also features built-in systems that help guard the engine and drive against damage due to mishandling, and its design and simple wiring make installation easy, reducing the time required for rigging and adjustment. The system offers precision control for single, twin, triple or quad installations as well as dual station operation. |

|

|

|

|

|

|

|

|

|